Overhaul / Repair Service

ORSKOREA has been overhauling and repairing various types of machines and spindles for well-known brands for over 20 years.

Our overhaul and repair experience can guarantee the best service to our customers.

ORSKOREA has been overhauling and repairing various types of machines and spindles from industry leading brands for 20 years.

Our overhauling and repairing experience can guarantee our clients with the best possible service.

Spindle Refurbishing / Repair Service

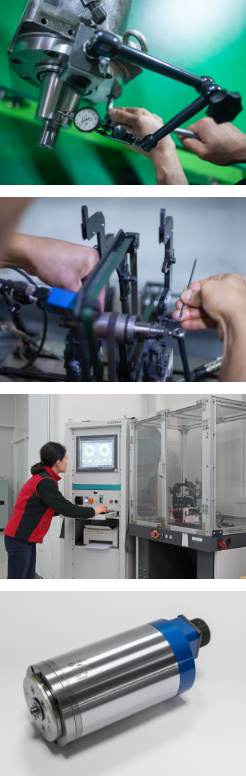

Check & Disassemble

- Do a visual inspection

- Disassembly – each step is photographed and analyzed in detail

- Each part is inspected and analyzed to determine if a replacement is needed

- Quotation will be provided for the client’s approval

Repair Service

- Clean the disassembled parts (by hand with ultrasonic wave and anti-rust chemicals)

- Purchase the spare parts (bearings and/or other necessary parts)

- Refurbish or provide necessary solution depending on product condition

- Design and re-manufacture of damaged parts (Done by qualified ORSKOREA’s senior members from design and manufacturing team)

- Adjust the balance of the parts including the shaft (balancing grade 1G or below based on ISO standard)

- Equipment’s use in the process: SCHENCK & SHIMATSU B.M brands

- Assembly and inspection (bearing is assembled according to appropriate preload level)

Precision Test & Trial Operation

- Accuracy test and test run before delivery

- Static precision test (run-out check)

- No-load test (minimum of 6 hours)

- Test run (check for bearings noise level and vibration using German SCHENCK equipment)

- Additional processing if balancing operation is needed

- Test run report will be provided including all data and work history

- Anti-rust and air sealed packaging for delivery

Grinding Machine Overhaul / Repair Service

Before